1 General

1.1 System Overview

A major challenge we face today is digitalization of industrial processes, extending machinery with low power, feature rich microcontroller-based electronics to collect sensor readings and forward data with LPWA communication channels to a Cloud Database in order to build up the “BIG DATA” - the knowledge base of the future. A mass of sensor readings needs to be organized into central databases for future processing so as to meet the expectations of Industry 4.0. The Internet of Things, or IoT provides the ecosystem to deal with this challenge. We review these potentials based on the IoT infrastructure system developed mainly for demonstration purpose by Endrich GmbH, a leading electronic spare part distributor in Europe, by showing an example how to work with a modem using Narrow-Band IoT technology and introducing the cloud based database service which was created by the company engineers to help IoT developers at the customers.

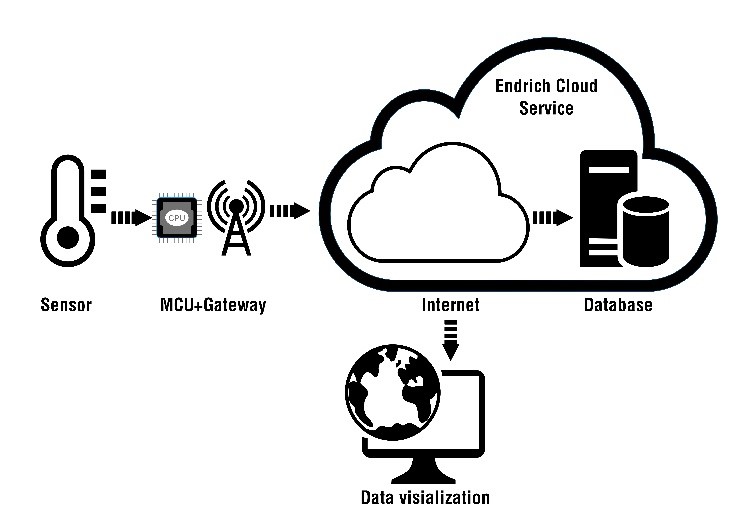

Endrich GmbH has developed an online sensor network infrastructure for the Embedded World exhibition, where every component of this hardware have been supplied by the manufacturers represented by the company. The beginning of the processing chain – like in a real-world application – consists of sensors detecting and measuring different physical quantities, which are processed all the way to cloud database storage and visual data representation at the end. There is a sophisticated gateway in between, which collects the sensor readings, preprocesses these data and sends it through a communication channel to a cloud based database service, where it can be displayed after processing, or used for any purpose appropriate for a given task.

The industrial expectations towards the complete infrastructure are high and diverse, including device, installation and maintenance cost minimalization, requiring many years of battery lifetime, high utilization of technological resources by all means, what can only be supported by competent component suppliers, having the professional background and also the willingness to provide development support and services. The first task is to select a proper microcontroller, and the major requirements are the appropriate number of available communication ports (GPIO, I2C, SPI, RS232, RS485, CAN, LIN etc.) for easy sensors interfacing, the low power consumption and a good and affordable software development environment. The microcontrollers of GigaDevice based on the RISC-V architecture can match the low development cost expectations (no ARM license needed) and meet all above technical requirements as well. In case of IoT sensor endpoints, - working mainly in isolated island mode - the lithium battery technology is the best response to power requirements, and this microcontroller family supports this due to its low consumption.

1.2 GD32V Risc-V and Arm® Cortex® M23 MCU series

Both the recently introduced ARM® Cortex® M23 based microcontroller family and the general purpose GD32V series of open source RISC-V architecture from GigaDevice are excellent choice as an MCU in IoT applications. GigaDevice provides full development tool support for both architectures from MCU chips to software libraries and development kits. The new devices are footprint and software compatible with the earlier GD32 microcontrollers. This unique and innovative feature ensures fast development cycle for both the GD32 Arm® core based GD32 MCU versions and for the new Risc-V architecture by making product selection and code porting flexible. These components are meant to be used in IoT applications from the “edge computing” to artificial intelligence programming. Implementation of low power system is supported by the two-level sleep feature ensuring the balance between the low stand-by current and quick wake up time.

The two-stage variable length pipeline microarchitecture of the Bumblebee core of the Risc-V controller reaches the performance and frequency of the traditional tree-stage pipeline architecture while keeps both power consumption and component cost low. These features let the GD32VF103 MCU series to process 153 DMIPS at maximum frequency and hit score 360 points on CoreMax® benchmark, which is 15% more power compared to the classic GD32 Cortex®-M3 core.

The low power Arm® Cortex®-M23 is also a microcontroller family designed for IoT, it is a successor of the Arm® Cortex®-M0 and Cortex®-M0+ platforms and based on Arm®v8-M architecture. Compatibility with all Arm®v6-M instruction set is maintained, it helps migration from Arm®-M0 / M0+ controllers, while the code execution efficiency of Cortex®-M23 is 30% (M0+) to 40% (M0) higher.

1.3 Narrow Band IoT Communication Modules

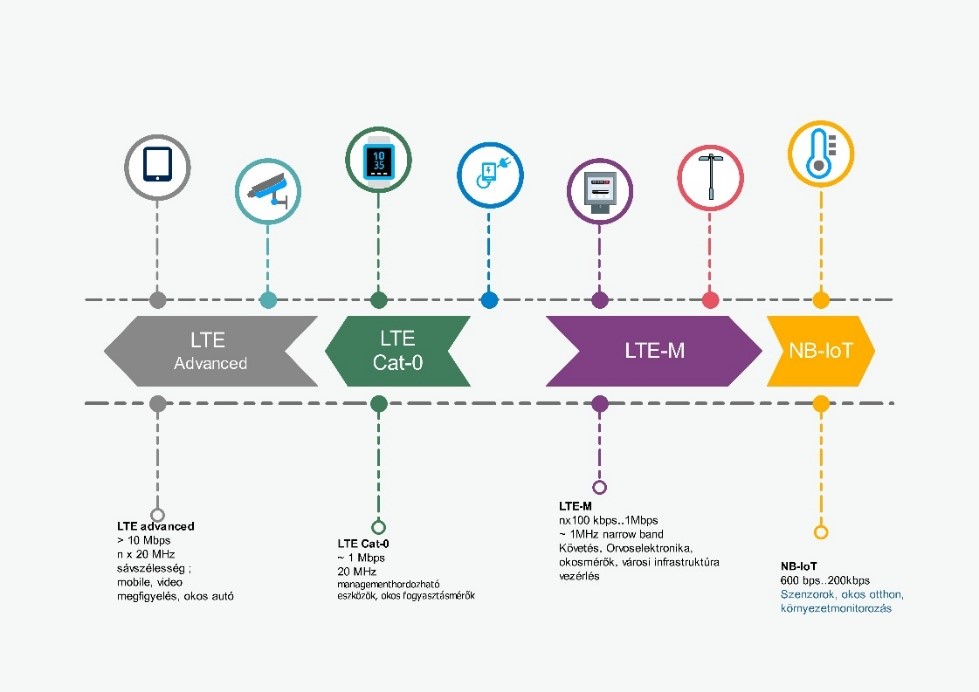

Data transfer for IoT can utilize many ways of LPWA (low power wide area) communication technologies, here we discuss one major area, which is the GSM based solution, an overview is shown on picture 2.

Today the majority of GSM based IoT applications (security and fire alarms, etc.) use the 2G network, however, there is a technological limitation in GPRS, the low maximum number of devices connected to the same cell. On the other hand, the shot down of the 2G network is expected soon, so other technologies specialized in M2M communication have come to focus. One of the popular solutions is the NB-IoT (narrow band IoT) standard, which is an extension of the current LTE technology. On other important technology is the LTE-M (Long Term Evolution for Machines), LTE-CAT-M1 which has specially been developed for M2M applications requiring higher data rate. The later has much higher bandwidth and requires more complex radio modules.

1.4 The benefits and keywords of NB-IoT are coverage, long battery lifetime, small device cost, best indoor penetration.

Cellular networks, so the LTE used by NB-IoT, have excellent coverage in urban area, however, the IoT endpoints with the sensors are often installed deep inside buildings, even in basements, where the traditional GSM (2G) modules needs high current – especially when the data link is being built up - to overcome the weak radio reception conditions. The NB-IoT technology, thanks to its extreme narrow carrier bandwidth, provides higher energy density which can penetrate deeper into the interior of buildings, and in case of extreme difficult reception conditions the reestablishing the data link becomes possible. The paid price of the good penetration is the low possible data rate. NB-IoT fits to applications where small datagrams are to be sent with long intervals in between, it is featured by minimal energy supply intake, thus extends battery life.

The usual GPRS/UMTS/LTE (2G/3G/4G) modules have many features and services which are not necessary for IoT devices, like voice communication, SMS service and broadband Internet. Skipping those features results simpler hardware, cheaper module price and lower power consumption.

The installation environment should be carefully checked before deciding to use NB-IoT technology:

- We need to check if the coverage conditions allow the use of the technology. (Is there coverage, and enough signal reception at the location of the sensor installation?)

- We need to check the required data communication profile, how often and what quantity of data have to be uploaded or downloaded (commands and updates).

- We need to calculate the energy supply requirements, check battery lifetime based on required current pulses by the working cycles of the device and the applied Lithium battery capacity and discharge characteristic. When large discharge pulses are expected (cell search, repeated data link connection), it may be necessary to back up the battery with a parallel super pulse capacitor, which can quickly supply a large pulse of energy for the module until the de-passivation process of the lithium primary (ER) battery lasts.

The factors above often lead to compromise, either lowering battery life expectations or selecting a larger capacity and longer lasting battery type.

1.5 FiboCom NB-IoT modules

The above facts underline the current market trend towards the large increase of the number IoT devices and the demand of connecting all those devices makes the NB-IoT technology unavoidable in next few years. Leading GSM providers have recognized the trend and introducing NB-IoT services one after the other. Endrich - based on her traditions - is supporting the trend from component side hand in hand with the suppliers represented.

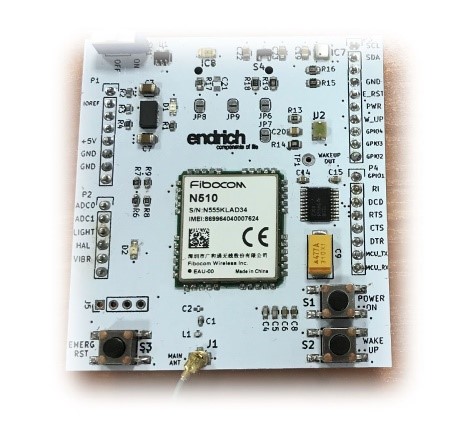

The MA510 and N510 modules by Fibocom are the most popular NB-IoT modems Endrich offers for the market.

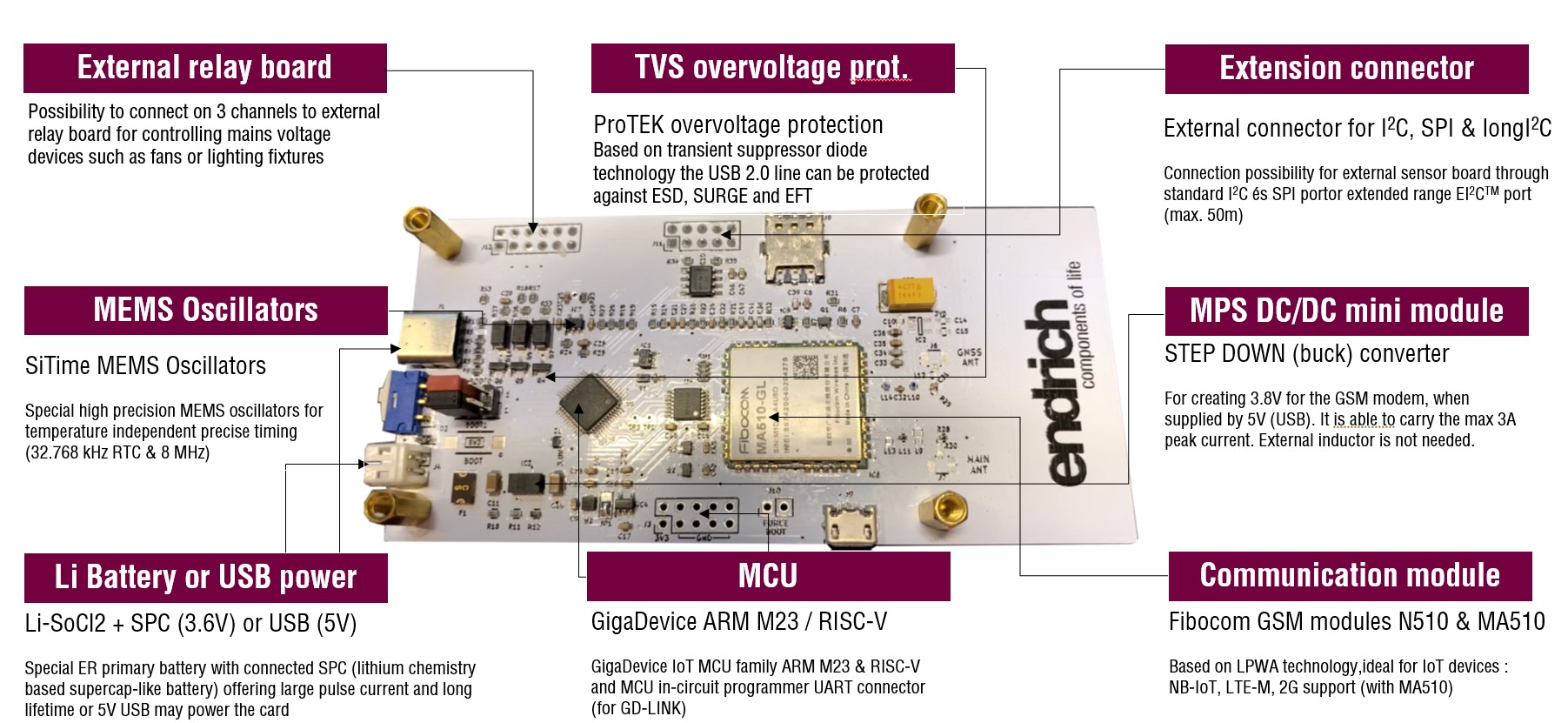

The brand-new Qualcomm MDM9205 based MA510-GL LPWA module variation connects to combinations of LTE Cat.M1, LTE Cat.NB2 and EGPRS networks, and supports global positioning (GNSS) via GPS / GLONASS / BeiDou / Galileo satellite systems. The modems are featured by low power consumption and utilize the good indoor reception of the narrow band IoT technology, thus can be used deep inside a building. The extreme competitive pricing matches the industrial requirements and paves the way for urban or agriculture applications as well. The module is a perfect device for low power applications requiring small amount of data transfer and allowing lower transfer time like device tracking, industrial data collection and control, security systems, smart homes and smart metering.

Fibocom’s other LPWA device is the MediaTek MT2625DP chipset based N510 NB-IoT only module, it can provide the longest battery lifetime and the lowest cost solution for such application as smart metering, city light control, smart parking, smart home and agriculture or fire alarms, where the main requirement is power saving – even to the level when a single primary battery can survive the entire life time of the device – paired with small and infrequent data transfer at minimum cost.

1.6 Endrich IoT infrastructure

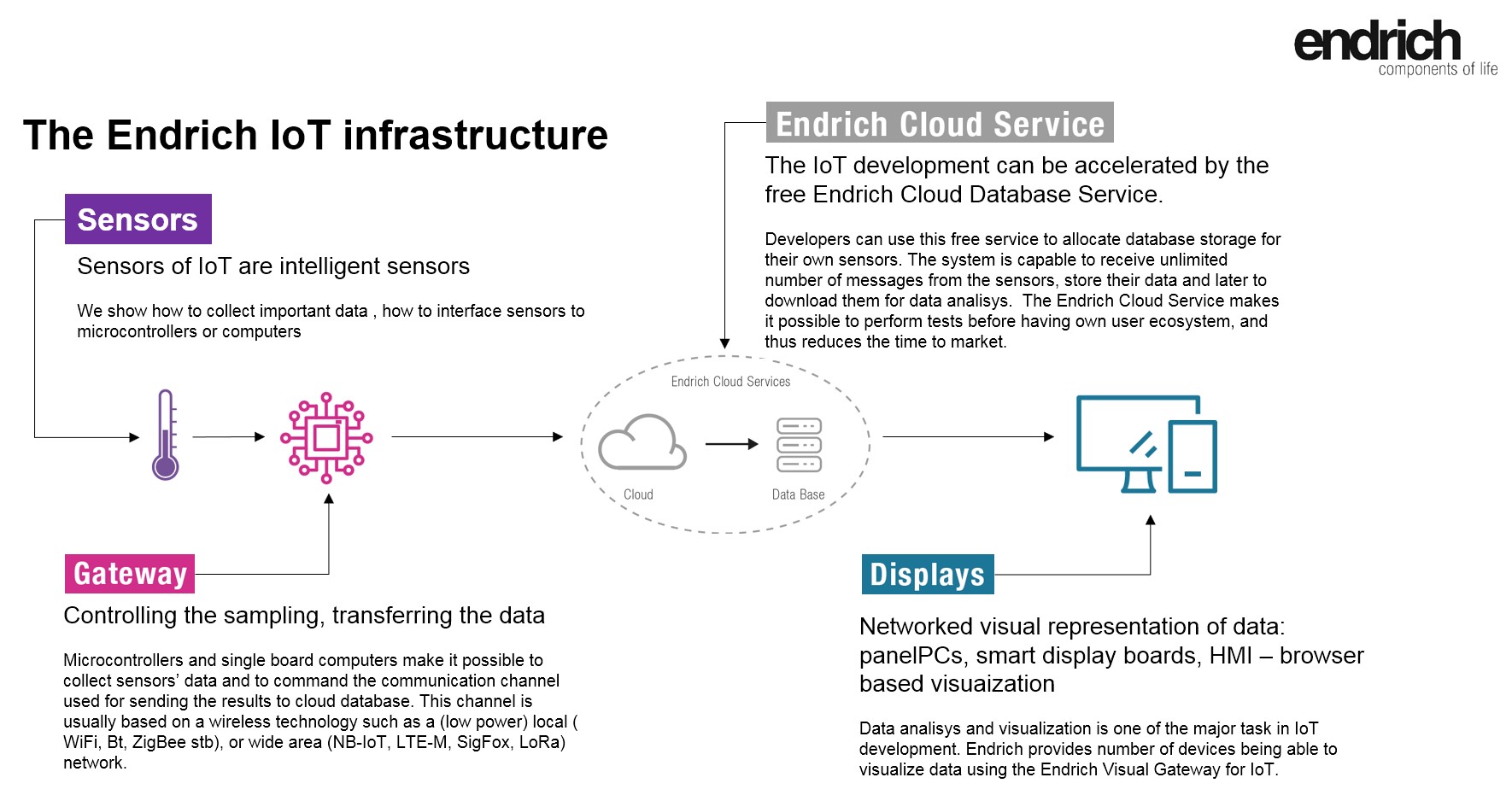

The sensor readings are usually stored for later processing in a database, typically in a cloud-based service, and the above-mentioned modules are suitable to implement data transfer between the electronics reading out the sensors and the database.

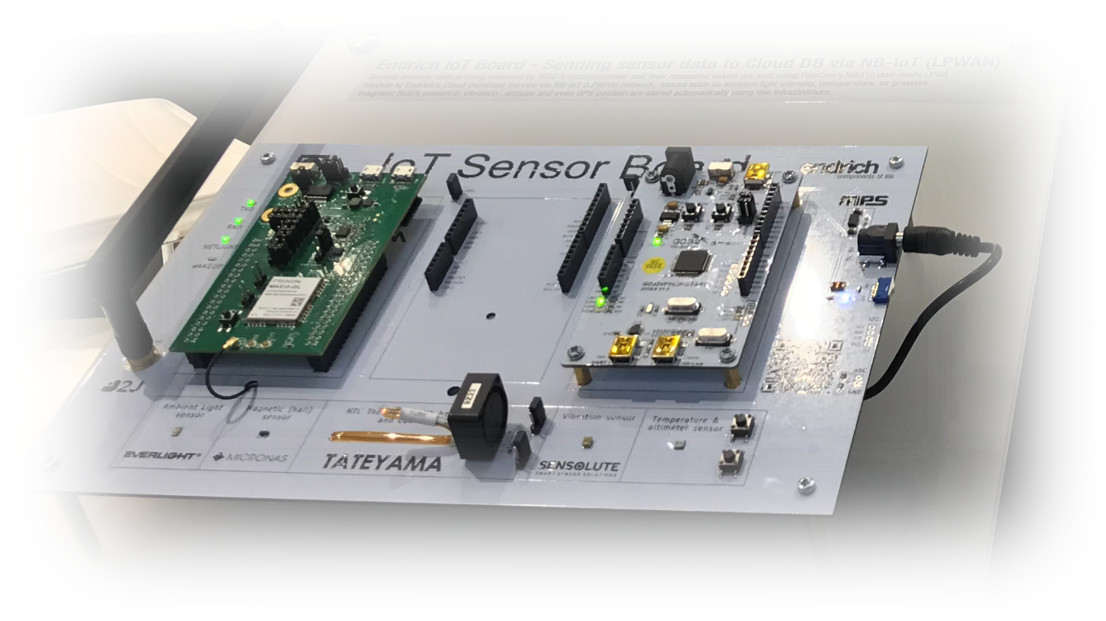

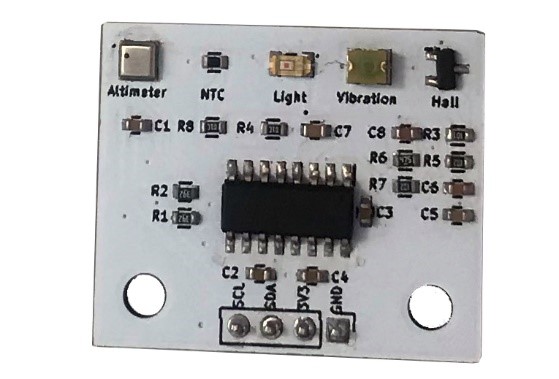

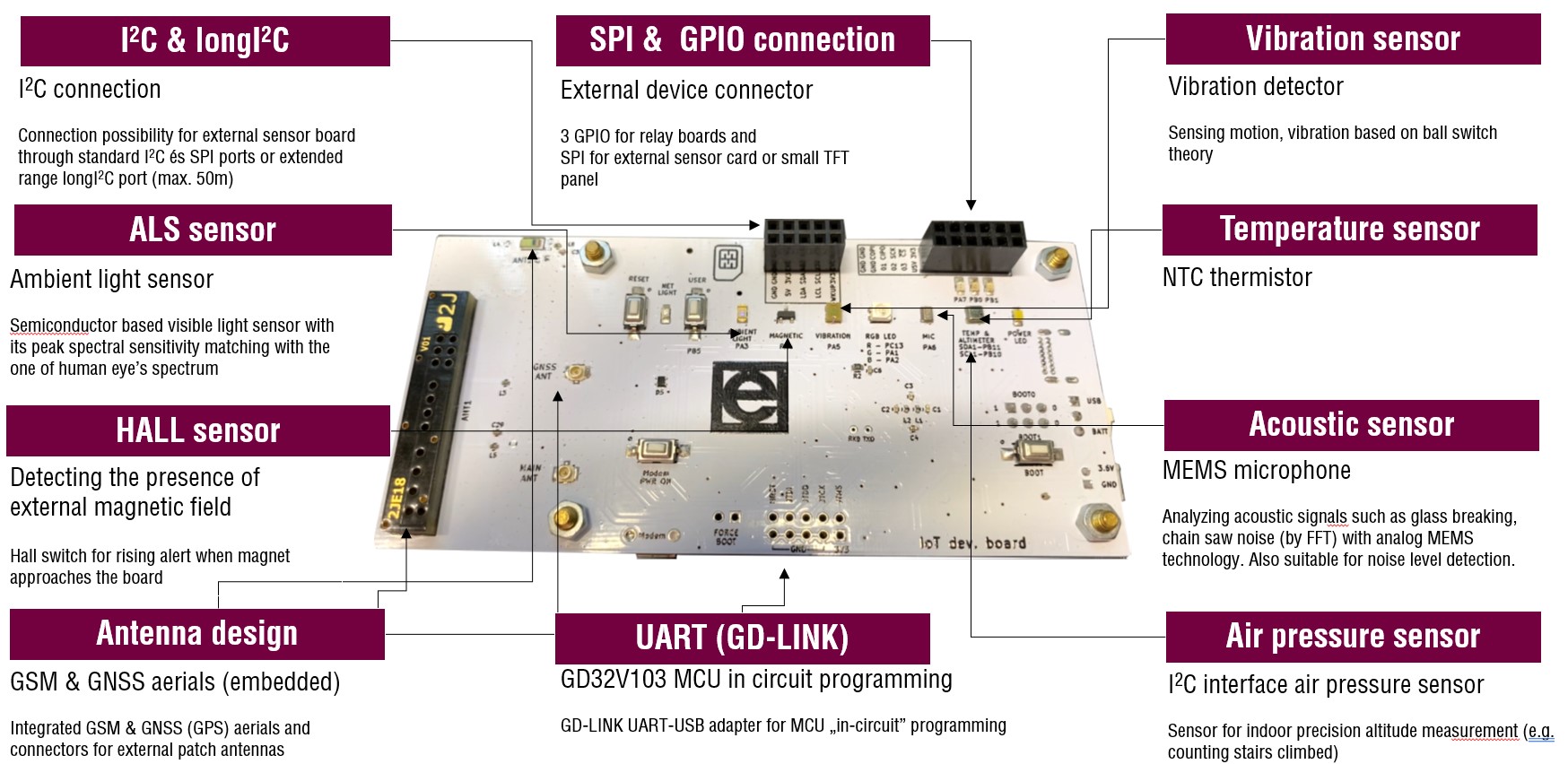

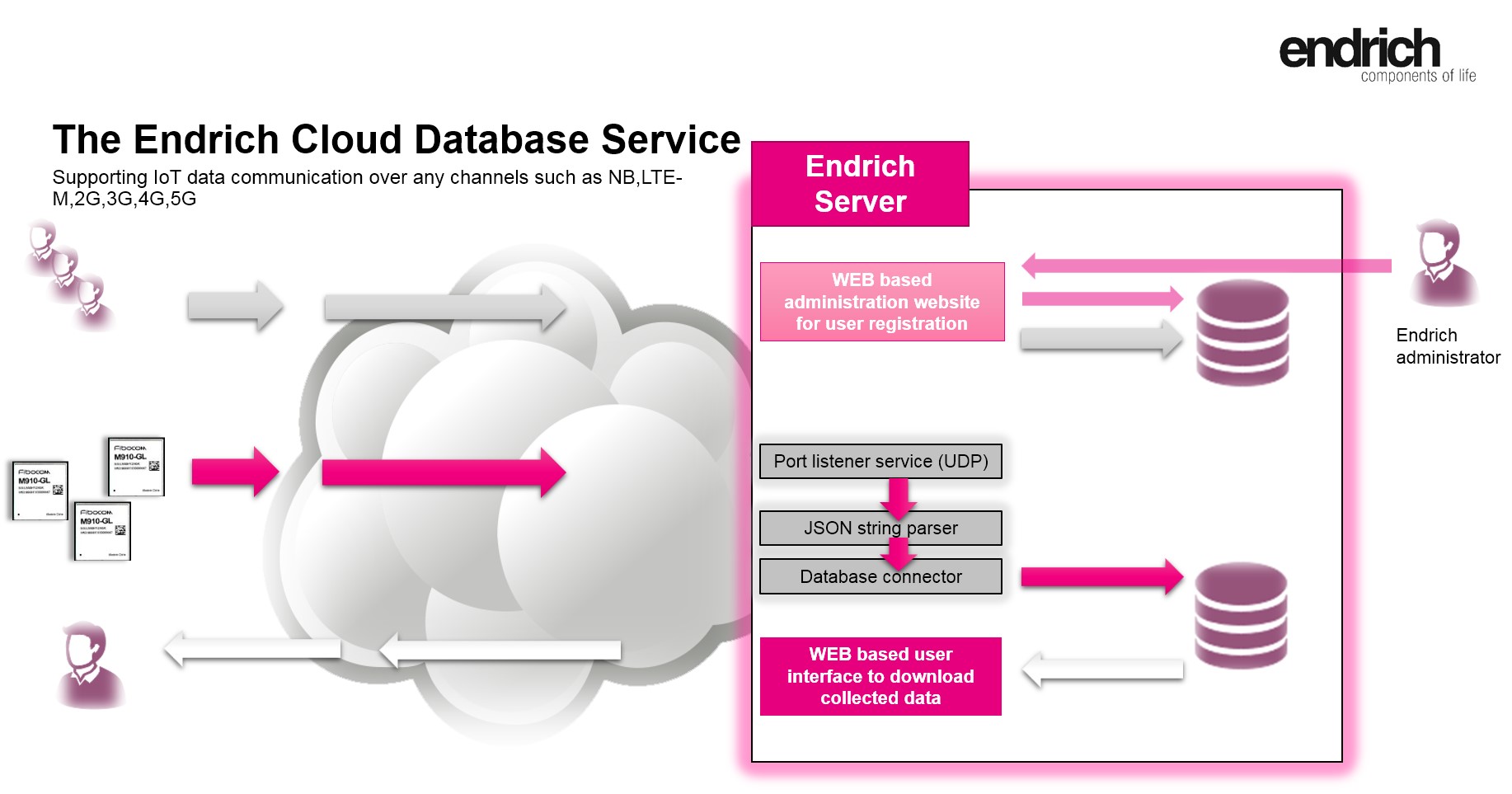

Endrich IoT concept is meant to implement this structure and provide hardware and software solutions to our partners in multiple levels. Endrich has started to develop - as the first step- a microcontroller driven sensor board equipped with narrow band GSM communication module. This Sensor & Communication Board as a hardware, together with the cloud based background network infrastructure (Endrich Cloud Database Service Software) offer a fully working concept of a general IoT solution, and it has been exhibited on national and international expos and conferences earlier in this year. Data provided by the Everlight ambient light sensor (ALS), the Tateyama and Semitec temperature sensors (NTC), the magnetic sensor from TDK-Micronas (Hall) and Sensolute miniature vibration sensor get collected by the newly developed GD32V103 RISC-V microcontroller from Gigadevice, and sent through the communication channel to the server. The telecommunication connection is implemented by a Fibocom MA510 module, which supports both NB-IoT and GPRS networks, and posts data using UDP protocol for storing in the Endrich Cloud Database Server – created for our partners. The panel size is for demonstration, a real application would be much smaller in size.

Endrich has also prepared an equivalent compact solution for other MCU platforms, so we can provide an IoT end point as a communication shield for third party MCU boards. This device fits to the commercial Arduino Leonardo boards, and also to GigaDevice evaluation kits for ARM® Cortex® M23 or RISC-V microcontrollers converting them to an IoT end point with sensing and communication capabilities. Endrich is providing this conceptual development infrastructure as a platform, not as a product, we still live on component sales, but supplement it with development support sharing reference circuit design, software code and providing access to our cloud database during the product development.

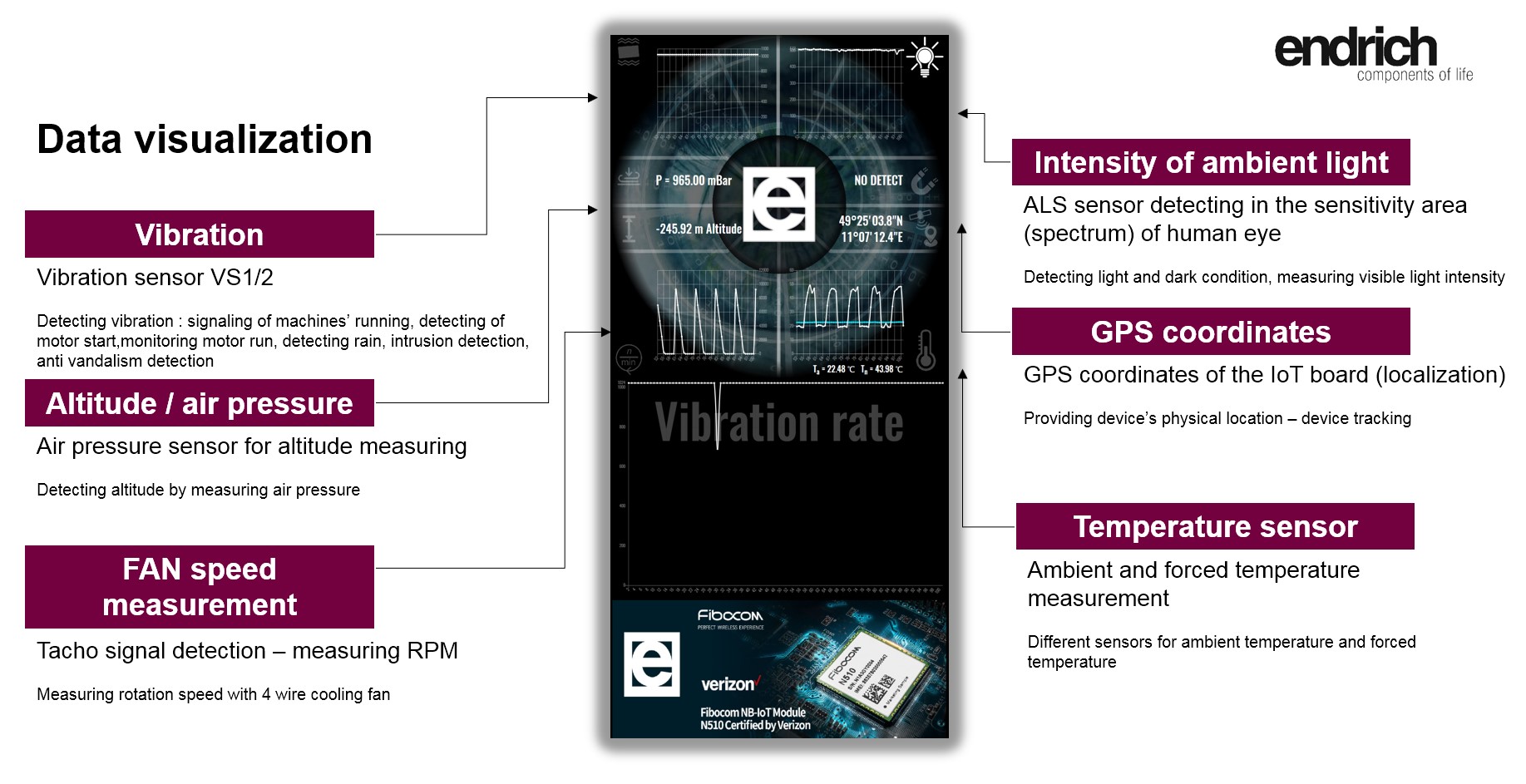

The third development step integrates all IoT functions (sensors, MCU and communication) into one single PCB (figure 8). The constructed IoT endpoint is capable of vibration and magnetic field sensing, ambient light intensity, temperature and air pressure measurement, altitude change calculation, and reporting the data through GSM network. This IoT board works autonomously as an island device powered by Lithium battery or USB power bank, and also reports GPS location thus can be applied even for vehicle superstructure tracking (such as cold storage or truck cargo compartment.)

The card has been equipped with an external I2C interface in order to connect a breakout sensor board in an extended range up to 50 meters. These customized breakout boards are available in various versions and variety and could also be used in combinations with customers’ own MCUs supporting I2C interface.

The IoT board acts as a development evaluation board for the IoT technology. Can be used as MCU evaluation, GSM modem evaluation. For this purpose, external connectors are available for the MCU and the Modem UART interfaces.

1.7 DATA VISUALIZATION

Data visualization is possible on any connected device, mobile phone, panel PC or industrial TFT monitor. The only requirement is a web browser, since the Endrich Cloud Database contains a WEB server providing visual display service. This interface can be customized in a certain level for customers’ own sensor applications.

We are happy to share the reference designs of the sensor interfacing, help microcontroller programming and selecting the best fitting components for any IoT applications our customers are developing. Our demonstration purpose devices are using advanced IoT technology, and help to review the operation of the sensors, to handle microcontroller data input and to implement wireless communication. We take care of the appropriate voltage leveling, power supply and converions. The card can be energized by advanced lithium primary battery, we are available for consultation on ER or CR batteries, rechargeable Li-ion accumulators or DC/DC converters or power supplies. We advise on MCU frequency control using MEMS oscillators, help in EMI issues and also overvoltage protection. Please browse the literature of our own publications in English or Hungarian language at electronics-articles.com

1.8 Endrich Cloud Database Service

Apart from our usual service to help finding and testing the appropriate components for a given IoT solutions, Endrich recognizing the need for background services, which also support development engineers providing cloud database service to administrate and store structured sensor data for later processing. The service can be used during evaluation and development until the developer is ready with his/her own cloud-based backend. The data is transferred in UDP channel using a predefined format and supports any number of end points.

Although Endrich is an international top 10 distributor being present is several countries, it used the expertise of Hungarian engineers for the above developments. I’d like to say thanks to Zsolt Veresegyhazy (Endrich) for software and Csaba Kocsis (Stars’Bridge) for hardware development contribution.

We are happy to organize online or personal demonstration, please address any question to the author at z.kiss@endrich.com